Understanding Perforated Stainless Sheets: Enhancing Your Business with Quality Materials

In the ever-evolving world of industrial manufacturing and metal fabrication, the need for versatile and durable materials is paramount. Among these materials, the perforated stainless sheet stands out as a remarkable solution for a variety of applications. This comprehensive guide will explore the significance of perforated stainless sheets, their benefits, applications, and essential considerations for businesses looking to integrate them into their projects.

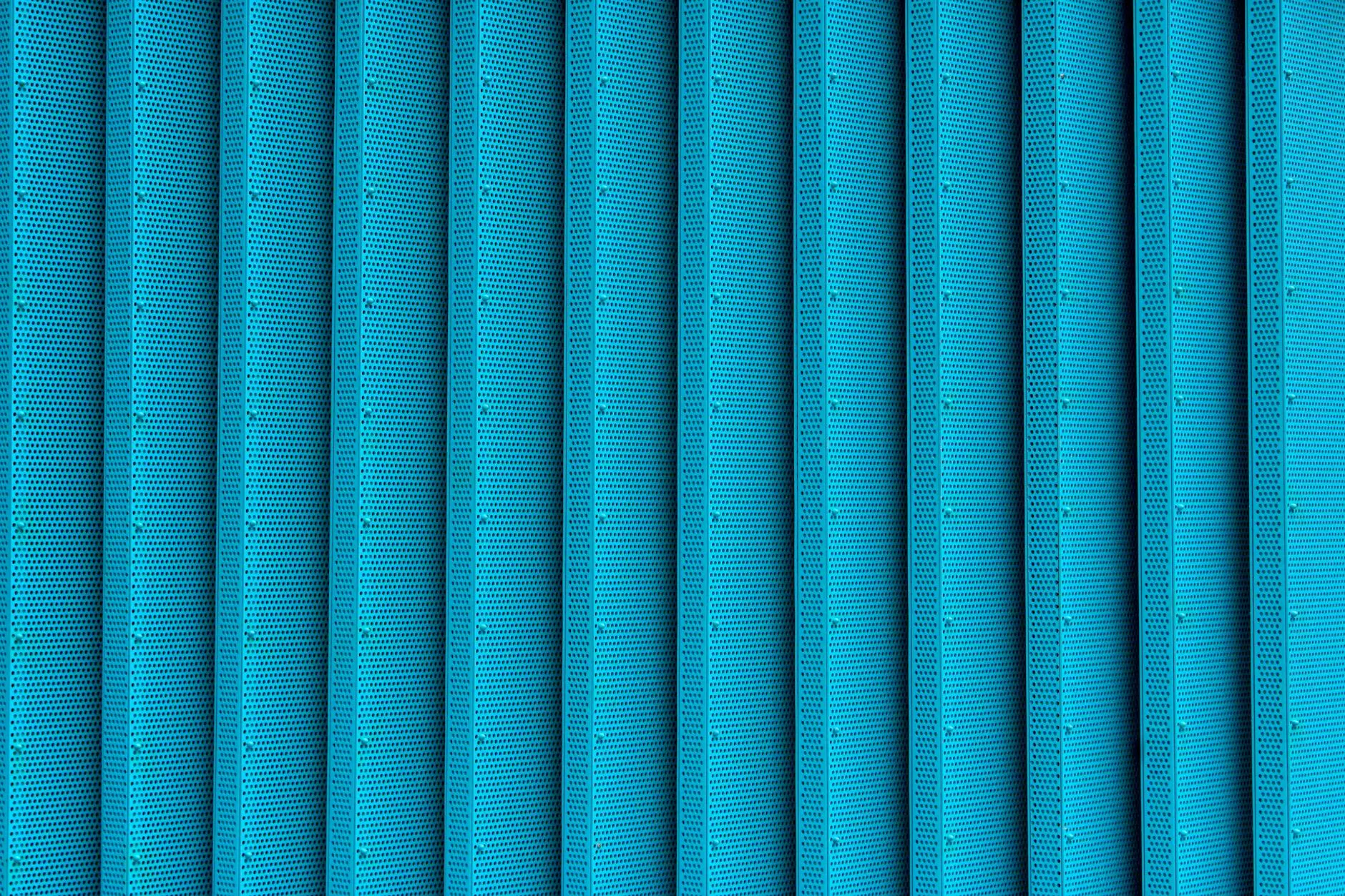

What is a Perforated Stainless Sheet?

A perforated stainless sheet is a flat sheet made of stainless steel that has been mechanically punched or stamped to create a series of holes or openings. This process not only enhances the aesthetic appeal of the sheet but also optimizes its functionality in various industrial and commercial applications. The flexibility in hole size, shape, and spacing allows for tailored solutions that meet specific requirements across diverse industries.

Key Advantages of Perforated Stainless Sheets

The use of perforated stainless sheets in industrial applications offers numerous advantages, making them a preferred choice among metal fabricators:

- Durability: Stainless steel is renowned for its resistance to corrosion, rust, and staining, which ensures longevity in various environments.

- Versatility: The customizable hole patterns enable the creation of tailored solutions, making them suitable for multiple applications.

- Lightweight: Despite their strength, perforated sheets are lighter than solid sheets, making them easier to handle and install.

- Enhanced Aesthetics: The unique patterns of perforation provide a modern and attractive look, appealing to designers and architects.

- Improved Air Flow and Light Transmission: The holes allow for better ventilation and illumination, making them ideal for uses such as filters and screens.

Applications of Perforated Stainless Sheets

Due to their unique properties and advantages, perforated stainless sheets are utilized in various sectors. Here are some of the most common applications:

1. Construction and Architecture

In modern architectural design, perforated stainless sheets are increasingly used for building facades, sunshades, and decorative panels. The perforations offer aesthetic value and serve functional purposes, such as controlling light and air while maintaining privacy.

2. Manufacturing and Industry

In manufacturing environments, these sheets are employed for protective barriers, machine guards, and enclosures. Their durability and robustness make them ideal for industrial settings where safety and performance are crucial.

3. Automotive Industry

Perforated stainless sheets find applications in the automotive sector for grilles, decorative elements, and sound dampening panels. Their lightweight nature contributes to overall vehicle efficiency.

4. Food and Beverage Production

The food industry benefits from using perforated stainless sheets due to their hygienic properties. They are often used in food processing equipment, filters, and as part of production machinery to ensure compliance with health standards.

5. Environmental and Acoustic Solutions

Perforated stainless sheets are often used in environmental solutions such as noise reduction panels, allowing sound absorption while maintaining structural integrity.

Choosing the Right Perforated Stainless Sheet

When selecting a perforated stainless sheet for your project, consider the following factors to ensure you choose the best material for your needs:

- Material Grade: There are various grades of stainless steel (e.g., 304, 316) known for their resistance to corrosion and suited to different applications. Evaluate the environment in which the sheet will be used.

- Hole Size and Pattern: The size and pattern of the holes should be selected based on the intended application, be it for aesthetics, ventilation, filtration, or light transmission.

- Sheet Thickness: The thickness of the sheet significantly impacts its strength and durability. Consider the load and stress it will need to withstand.

- Finish: The surface finish (e.g., polished, brushed) affects both the appearance and the corrosion resistance of the sheet.

- Custom Fabrication: In some cases, you may require additional fabrication services such as cutting, bending, or welding to meet specific project specifications.

The Process of Manufacturing Perforated Stainless Sheets

The manufacturing of perforated stainless sheets involves several steps, each contributing to the quality and functionality of the final product:

- Material Selection: The process begins with the selection of high-grade stainless steel that meets the required specifications.

- Design Phase: Engineers create the desired perforation pattern using CAD software, ensuring precise measurements and configurations.

- Punching: The selected sheet is punched using CNC machines or specialized perforating presses to create the predefined hole patterns.

- Finishing: The sheet undergoes finishing processes such as deburring, polishing, or coating to enhance its performance and appearance.

- Quality Control: Rigorous testing and inspection are carried out to ensure the sheets meet industry standards before being dispatched for use.

Conclusion: Elevating Your Business with Perforated Stainless Sheets

Incorporating perforated stainless sheets into your business can lead to significant enhancements in functionality, aesthetics, and efficiency. Whether you are involved in construction, manufacturing, or design, these sheets play a crucial role in delivering the quality and performance required in today’s competitive landscape.

By understanding the features, benefits, and applications of perforated stainless sheets, you can make informed decisions that will positively impact your projects. For those in the metal fabricators sector, partnering with a trusted supplier like Goldecosteel.com ensures access to high-quality materials that can meet diverse needs and exceed expectations.

For further inquiries and to explore our range of perforated stainless sheets, feel free to contact us, and let us help you elevate your business through quality metal fabrication.